High Temperature PTFE belt & Tapes

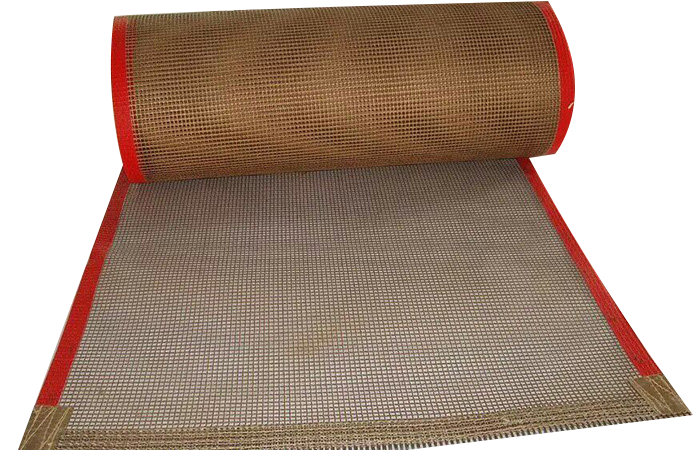

We are supplying Teflon and PTFE High temperature Food belt for Conveyor application. We have a facility to develop belts as per customize size. We are importers of PTFE and Teflon belt.

TO Develop Belt

To customize development for High temperature belt or PTFE belt, we need sample belt or Drawing of belt. And Operational information, Technical information, and Working environment Detail. If you don’t have No worry our specialist will take visit at your facility to get this information. We are happy to help you.

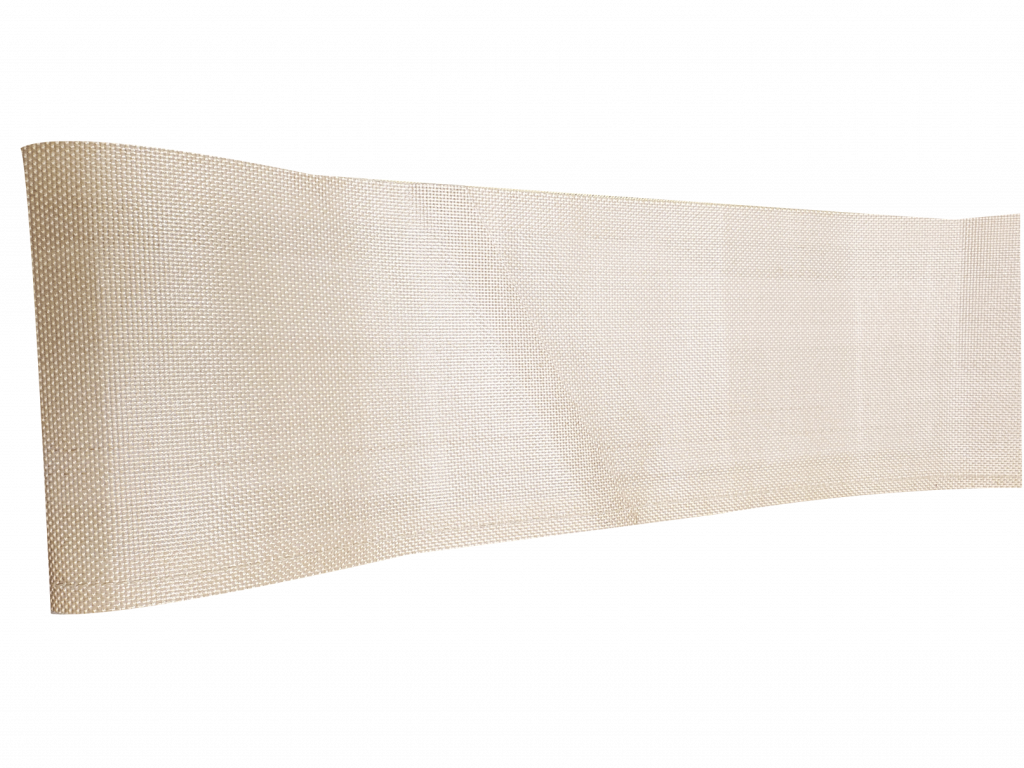

We are importing Special type PTFE material having a combination of aramid and Teflon to fulfill the Food application conveyor belt.

We also import PTFE related material like, tape, Kevlar guide. PTFE is widely used in food application because the non-toxic, tasteless and odorless qualities of the PTFE coating make it appropriate for use in food handling operations.

Our belting comes in a variety of proprietary coating formulas and With a variety of splices, edging & tracking mechanisms, and installation accessories, Alps tech solutions can provide you with a solution suited for your specific application.

Advantages

- Significantly extended belt life

- Flat surface with few catch points improves product yield and reduces crumb waste

- Belt design and surface properties minimize oil carryover

- Easier to repair; reduction in unscheduled downtime from belt ‘crashes’

Application

- Continues contact grilling

- Bakery conveyor belt

- Food drying belt

- Salad and Vegetable washing belt

- Tortilla and Pizza dough processing

- Pasta Steaming belt

- Side Sealing Belts for Paper Packaging

PTFE Belts and belting materials are available for applications that require superior release characteristics, permeability for rapid drying, dimensional and thermal stability, and the dynamic strength to stand up to the most rigorous operating conditions.

The unique behavior of these materials results in a product that is more practical and cost-effective than conventional belting materials.We are using the ARAMID CORD for tracking the control guide of the belt. A braided aramid cord stitched to belt edge aligns with grooves in a grooved roller tracking system.

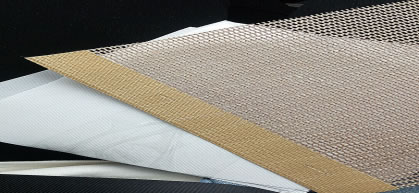

We have different types of PTFE and Teflon belt material which specification as below.

Mesh Size | material | Thickness | Weight | Temperature resistance | Max Width | Tensile Strength |

1x1mm | fiberglass | 0.5mm | 370g/m² | -70-260℃ | 4000mm | 310/290N/cm |

2x2mm | fiberglass | 0.7mm | 450g/m² | -70-260℃ | 4000mm | 350/310N/cm |

4x4mm | fiberglass | 1.0mm | 400g/m² | -70-260℃ | 4000mm | 390/320N/cm |

4x4mm | fiberglass | 1.0mm | 450g/m² | -70-260℃ | 4000mm | 390/320N/cm |

4x4mm | Kevlar + fiberglass | 1.2mm | 600g/m² | -70-260℃ | 4000mm | 895/370N/cm |

4x4mm | fiberglass | 1.2mm | 580g/m² | -70-260℃ | 4000mm | 560/360N/cm |

4x4mm | Kevlar | 1.0mm | 500g/m² | -70-260℃ | 4000mm | 900/600N/cm |

4x4mm | fiberglass | 1.0mm | 550g/m² | -70-260℃ | 4000mm | 395/370N/cm |

10x10mm | fiberglass | 1.2mm | 450g/m² | -70-260℃ | 4000mm | 360/300N/cm |

0.5x1mm | fiberglass | 0.5mm | 420g/m² | -70-260℃ | 4000mm | 310/290N/cm |

2×2.5mm | fiberglass | 0.9mm | 600g/m² | -70-260℃ | 4000mm | 390/320N/cm |